Close

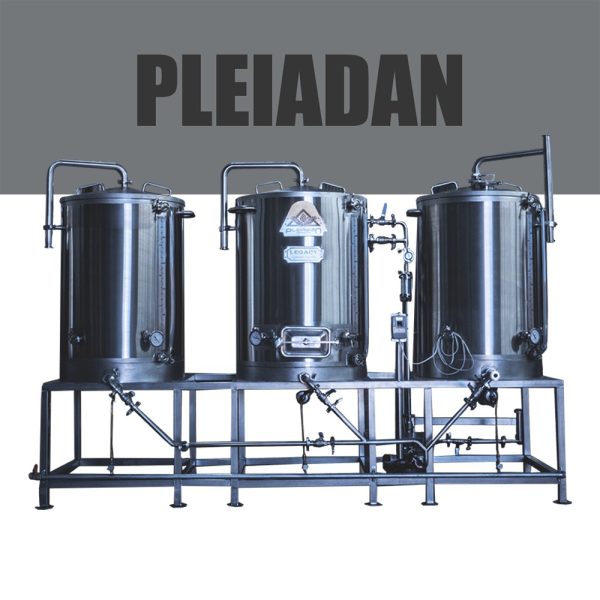

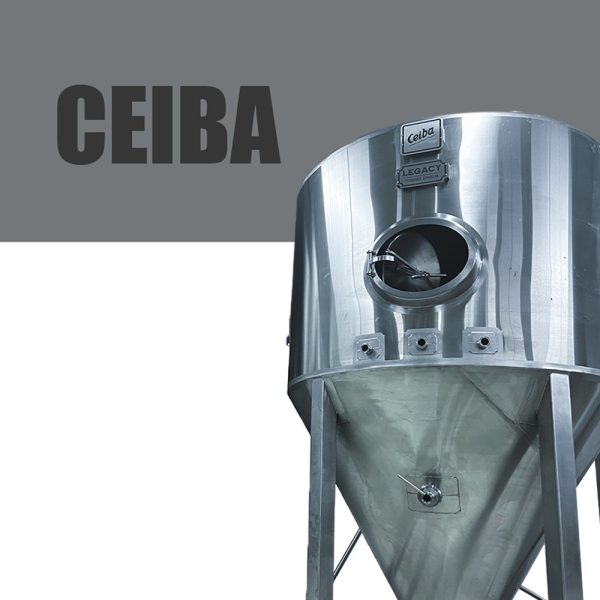

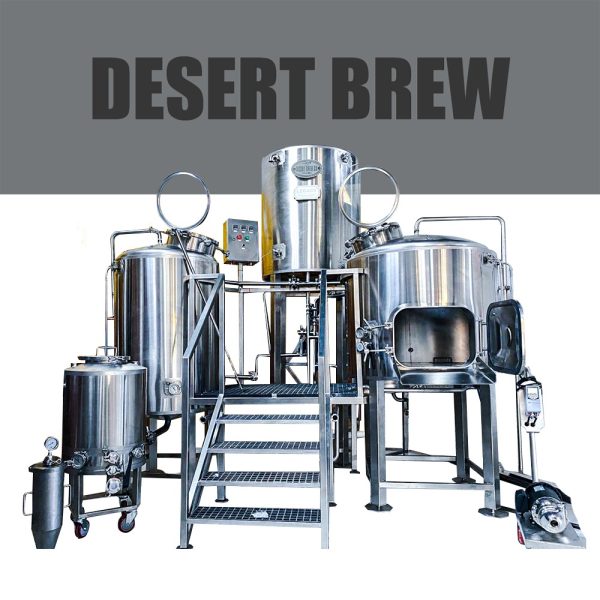

As long as the temperature is controlled, you have nothing to worry about. Legacy's brewing or process tanks are designed to protect your product. Made of 12 gauge 304 stainless steel with a food grade sanitary finish and with the proper headspace according to the type of tank, your product will be safe throughout the process.

Llena el formulario de abajo para recibir noticias y promociones exclusivas:

Si tu interés de contactarnos es para ofrecernos algún producto o servicio, por favor envía tu información a: proyectos@legacytc.mx